Fleet maintenance refers to a comprehensive service that ensures the vehicles are running and also it’s the process of making sure that everything relating to the vehicle is in check including the operation, the safety, and the lucrativeness of your whole business. Efficient, cost-effective fleet maintenance cannot be stressed enough no matter your managing scope; whether it is a small fleet of 10 vehicles or a large-scale operation with hundreds. The risk of vehicle downtime can possibly have a domino effect on operations, customer satisfaction, and overall costs in a company that heavily relies on vehicles for customers’ service, goods transport, or services providing.

We will discuss the importance of fleet maintenance, how it contributes to the success of a business, and the software that makes the whole process of fleet maintenance a more efficient, streamlined operation. Let’s begin!

What is Fleet Maintenance?

Fleet maintenance is the process that involves routine inspections, servicing, and repairs of the vehicles in a fleet to make sure that they run smoothly, are up to the safety standards, and do not suffer from sudden breakdowns. A good fleet maintenance strategy has the following objectives:

- Avoid unexpected breakdowns and reduce repairs that are expensive.

- Increase the life span of your fleet.

- Facilitate the safety of drivers and pedestrians.

- Make sure that your fleet is within the limits of the regulations set by the government.

In short , fleet maintenance is a must for successful fleet operation. It is the foundation of fleet maintenance that drives business operations. Frequent downtimes, higher repair costs, and even the risks surrounding your drivers and their vehicles are all consequences of the absence of fleet maintenance.

Why Fleet Maintenance Matters

Fleet maintenance is a primary component of the total fleet management plan. Here are some reasons why it should come first:

1. Prevent Unexpected Breakdowns

Nothing disrupts a smooth operation more than a sudden breakdown of a vehicle during a trip. Be it a flat tire, engine malfunction, or brake failure, these breakdowns incur both money and time costs. Regular maintenance of the fleet helps to detect the minor problems early before they escalate into major ones, thus cutting the chance of sudden breakdowns that can cause the stopping of your operations.

2. Extend Vehicle Lifespan

Vehicles are a substantial investment, and it is advisable to stretch their life to the maximum. The combination of routine servicing, prompt repair, and proper upkeep helps to maintain the engines, brakes, and other parts at their best performance levels, thus allowing the vehicles to be dependable for many years. All of this results in less frequent costly replacements and thus, the full realization of your investment.

3. Enhance Driver and Road Safety

Fleet maintenance is closely linked to driver safety. A properly maintained vehicle is unlikely to suffer critical problems that might endanger the drivers. Regular inspections of tires, brakes, and lights help to confirm that the vehicles are in good condition for the road and that the drivers are in a safe environment.

4. Ensure Regulatory Compliance

Vehicles in numerous sectors have to fulfill certain safety and performance requirements. Fleet upkeep is the way to making sure your vehicles meet regulations thus lessening the chances of incurring fines, penalties, or in the worst case, being shut down due to non-compliance. Also, through it, you will be ready for inspections and audits.

5. Control Fleet Spending

The cost of proactive maintenance is much less than that of reactive repairs. If you keep a stringent schedule for regular check-ups and services, you will be able to avoid costly repairs that could have been averted if timely maintenance was carried out. This tactic, though seemingly costly in the short term, is a money-saver in the long run and will thus affect your bottom line positively.

Types of Fleet Maintenance

Fleet maintenance varies according to the different needs and conditions of the fleet. The three main types of fleet maintenance can be classified as follows:

1. Preventive Maintenance (PM)

Preventive maintenance is the scheduled servicing of the vehicle at regular intervals determined by either time, mileage, or engine hours. The maintenance’s goal is to prevent breakdowns by taking care of potential problems before they happen. For instance, oil changes, tire rotations, and brake testing are all examples of preventive maintenance that can help reduce breakdowns by as much as 70%. Therefore, it is a crucial part of every fleet maintenance strategy.

2. Predictive Maintenance (PdM)

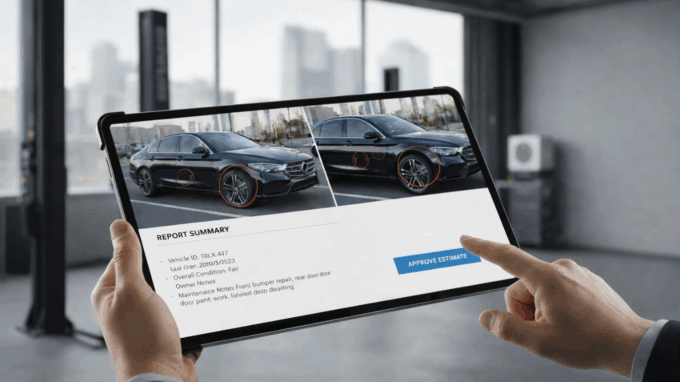

Predictive maintenance takes the process a step ahead by employing data, diagnostics, and real-time vehicle monitoring to forecast possible issues before they occur. Through the examination of trends in sensor data, fleet managers can spot worn-out components and rectify them before driving the vehicle into a halt. Predictive maintenance is entirely dependent on fleet maintenance software and IoT sensors.

3. Reactive Maintenance

Reactive maintenance, which is often called corrective maintenance, means the repairing of a vehicle after it has broken down. It is an inevitable aspect of fleet management but is usually more expensive and inconvenient than preventive or predictive maintenance. Therefore, minimizing reactive repairs should always be a target in your fleet maintenance program.

Key Elements of an Effective Fleet Maintenance Program

A fleet maintenance program that works well is the one that utilizes various strategies and tools combined to complete the whole process efficiently. Below mentioned are the key elements every fleet manager must integrate:

1. Maintenance Scheduling

Fleet managers should set a precise schedule relying on the vehicle use patterns, the manufacturer’s recommendations, and the odometer readings. When maintenance is scheduled properly then the vehicle is serviced and the risk of major breakdowns is reduced.

2. Digital Maintenance Logs

Replacing the traditional paper logs with digital records brings about quicker maintenance tracking. Maintaining digital logs brings about faster audits, easier access to service history, and better evaluation of the fleet’s status.

3. Vehicle Health Monitoring

Fleet maintenance software, supported by real-time data and diagnostics, has the capability to monitor vehicle health and notify fleet managers about problems such as battery drainage, engine overheating, or trouble codes of the engine. This preventive measure is a major contributor to the lessened possibility of breakdowns.

4. Trip Data Verification

Keeping an eye on drivers’ behavior and checking trip data assists in spotting any driving that is strenuous or irresponsible and could lead to the premature aging of the vehicles. Actions like hard braking, speeding, and rapid acceleration can eventually harm the fleet of vehicles, thus raising the issue of maintenance cost.

5. Parts and Inventory Tracking

The parts inventory management system guarantees the availability of the essential replacement parts at all times. Consequently, the downtime is reduced and the repairs are done quickly when a car needs care.

6. Driver Behavior Monitoring

It is highly recommended that the fleet managers keep an eye on the driver’s behavior. The use of practices such as harsh braking, quick acceleration, and speeding will result in the faster degradation of the vehicle. The driver behavior monitoring can be accomplished with the help of fleet maintenance software that will also provide suggestions for improvement.

Common Challenges in Fleet Maintenance

The management of a fleet has been, and still is, a source of many problems. Among other things, the fleet managers are having to deal with these issues:

- Manual spreadsheets and records full of errors: The outcome is that mistakes cost a lot and the maintenance schedule is overlooked.

- Service records that are either lost or incomplete: The business will have to go through a long and frustrating process of audits which might result in a fine if the records cannot be located.

- Sudden breakdowns due to the service being done too late: If one does not service the vehicle frequently enough, it will break down when least expected.

- Uncertainties around the repair costs: Fleet managers have no way of accurately tracking and forecasting their expenditures on repairs.

All these problems will lead to prolonged downtimes, high repair costs, and unhappy drivers. But on the other hand, maintenance software for fleets could be able to solve these issues and make the whole process easier.

How Fleet Maintenance Software Simplifies Maintenance

Fleet maintenance software gives fleet managers the means to monitor vehicle condition and schedule services on time. The following are the main points of how:

- Automated Service Reminders: The fleet maintenance program issues automatic alerts about an upcoming vehicular service based on the readings from the odometer, set intervals of time, or the hours of operation of the engine.

- Accurate Odometer Tracking: This program ensures that there will be no mistakes in the odometer readings and no one can tamper with the data by tracking the odometer readings in real time.

- Real-Time Vehicle Health Alerts: You will be receiving instant notifications for all the issues that a vehicle may have like, for example, engine defects, dead battery, or malfunctioning sensors.

- Digital Maintenance Records: There is a digital record for all servicing and repairs that is readily available for audits and compliance checks as the records are very easy to access.

- Repair Cost Tracking: By using fleet maintenance software, you can monitor and assess the expense of maintaining each individual vehicle which will allow you to spot patterns and come up with educated guesses.

Benefits of Fleet Maintenance Software

Using fleet maintenance software offers several advantages for fleet managers:

- Reduced Breakdowns: Timely service reminders and live monitoring of vehicle health together prevent unexpected breakdowns.

- Lower Operational Costs: Preventive maintenance work done and correct tracking of repair costs result in a more efficient operation of the fleet.

- Higher Uptime of Vehicles: By performing maintenance prophylactically, vehicles could be on the road more and in the repair shop less.

- Improved Decision-Making: The software generates insights based on data that support fleet managers in making quicker and better decisions.

- Longer Vehicle Lifespan: Regularly maintained vehicles last longer which in turn means fewer and less expensive replacements.

Fleet Maintenance Best Practices for 2025

In order to maintain an efficient fleet in 2025, give a thought to the following practices as the best ones:

1. Adopt a Preventive Maintenance Calendar: Always follow the scheduled service and never miss or hold it back. It will be cheaper for you in the long run.

2. Automate Odometer-Based Servicing: The real-time data should be used for monitoring the mileage which will make the servicing timely.

3. Digitally Track Service Logs: Have a single database for all service records so they can be quickly accessed during auditing and compliance checking.

4. Driver Behavior Monitoring: Implement a software that will tell you if a driver’s habit of driving is harsh and therefore leading to extra wear on the vehicle.

5. Weekly Fleet Health Review: Keep on continuously monitoring the condition of the vehicle and the scheduled services to be able to catch the problems before they arise.

Conclusion:

The fleet maintenance process is no longer manual and reactive; rather, it is now, a strategic data-driven approach that optimally utilizes vehicle uptime, enhances safety, and cuts down costs. Comprehensive fleet maintenance software for fleet managers brings them the health of their fleets, through which they are able to take wise decisions and thus, become more profitable.

Preventive and predictive maintenance are to be prioritized by using fleet management tools and making sure drivers adhere to the best practices; this way businesses can have their fleets running perfectly for many years. A fleet in good condition is a fleet that brings in profit, and maintenance is the secret to lasting success.