The transportation industry experiences major changes because of AI technology and cloud-based systems which transform its operations. The field has experienced a major change because predictive maintenance allows organizations to prevent costly breakdowns through data analysis and intelligent software systems which detect problems at their earliest stages.

The conventional method of fleet maintenance operated through two main approaches which involved either waiting for equipment to fail before performing repairs or following predetermined maintenance schedules. The maintenance strategy for fleets followed two main approaches which involved either fixing vehicles after breakdowns or performing scheduled maintenance at predetermined times. The traditional maintenance system for fleets operates through two main approaches which include responding to breakdowns with repairs and performing maintenance at scheduled intervals.

Managers would either fix vehicles after a breakdown or perform routine checks regardless of the vehicle’s actual condition. The maintenance strategies prove somewhat useful yet they generate excessive expenses and consume excessive operational periods.

Enter predictive maintenance software. Fleetblox operates through a platform which combines Fleetblox with telematics systems and AI diagnostics and cloud analytics to provide continuous monitoring of fleet health. The method enables supervisors to detect problems at their onset which enables them to create maintenance plans that boost fleet performance.

The blog will explain predictive maintenance and its software operation and show fleet operator advantages and demonstrate Fleetblox’s impact on fleet management.

What is Predictive Maintenance?

Predictive maintenance (PdM) is a proactive maintenance method that utilizes real-time data and analysis to predict when equipment failure might occur before it happens. In contrast to preventive maintenance, which relies on preset intervals, predictive maintenance is based on actual conditions of the vehicle, which is much more effective.

In fleet management, predictive maintenance is used to monitor the health of key vehicle components, like engines, brakes, batteries, and tires. Throughout this process, fleet managers are detecting anomalies or signs of wear early in order to avoid the risk of an unplanned break down, reduce maintenance costs, and extend the life of the vehicle.

Key Points:

- Utilizes sensor data from vehicles to monitor health

- Utilizes AI and machine learning to identify patterns and assess when failures are likely to occur

- Optimizes the intervention schedule based on actual needs, not fixed intervals

- Minimizes downtime, and higher fleet reliability

How Predictive Maintenance Software Operates

Predictive maintenance software works by bringing together vehicle telematics data with cloud computing systems and AI analytics to produce useful operational insights. The following description summarizes how fleet operations generally function:

1. Real-Time Vehicle Monitoring

Modern fleet vehicles have sensors that provide the monitoring of engine temperature and fuel consumption and brake performance and battery condition and other vehicle system data. The predictive maintenance software system collects all data continuously so that it can create a real-time assessment of vehicle condition.

2. Data Analysis and Predictive AI

The entire procedure begins with data gathered from various sensors in the machines and this data is processed through machine learning algorithms that recognize patterns to spot anomalies, thus assisting with predicting the breakdowns in advance. A case in point, if the engine is producing an unusual vibration, this could be an early signal of a failing part.

3. Automatically Generated Notifications and Recommendations

The predictive maintenance software systems issue alerts, which the fleet, managers promptly get when the system detects potential equipment problems. Following this, the software might propose certain maintenance activities such as changing parts, setting up services, and conducting diagnostics.

4. Cloud-Based Reporting

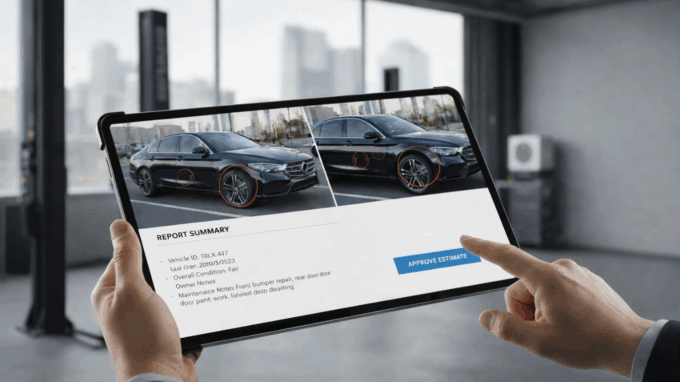

Solutions like Fleetblox store and analyze all vehicle data in the cloud, providing fleet managers with easy-to-read dashboards and detailed maintenance reports. The system enables better decision-making through centralized fleet management which works for organizations that operate across different locations.

Predictive Maintenance Solutions for Fleet Managers

Fleet managers can choose between different predictive maintenance solutions which include basic tools and complete software systems.

AI-Powered Fleet Maintenance Platforms

The vehicle monitoring system of Fleetblox operates through a single platform that combines predictive analytics with cloud-based solutions.These platforms eliminate the need for traditional hardware installations and provide:

- Continuous vehicle condition monitoring

- AI-driven diagnostics for early issue detection

- Automated maintenance scheduling

- Comprehensive fleet performance insights

Predictive Maintenance Tools

Fleet managers can use specific predictive maintenance tools which operate independently from complete software platforms to support their operations.

- Real-time data collection through telematics devices enables organizations to collect immediate information.

- The maintenance management dashboards enable organizations to schedule repair activities and track their status from the start to the finish of maintenance operations.

- AI analytics engines that generate predictive insights

- The system alerts users through automated notifications which serve as early warning signals.

The tools operate as a full predictive maintenance system through their integration with Fleetblox software which enhances operational performance by minimizing equipment breakdowns that occur without warning.

Advantages of Predictive Maintenance for Fleet Management

There are a variety of benefits associated with investing in predictive maintenance software for fleet operations. This technology can be called a game-changer for many reasons:

1. Decreased Downtime

Predictive maintenance technology predicts maintenance needs before a break-down occurs so fleets have fewer unplanned outages, thus keeping vehicles in service and meeting delivery schedules.

2. Reduced Maintenance Expense

Predictive maintenance allows fleets to resolve minor issues early, which prevents costly repairs. This technology will proactively lower overall maintenance cost over time.

3. Increased Lifespan of Vehicles

Tracking vehicle health and maintaining parts throughout their lifespan, provides adequate time for critical components to function as intended. This technology also helps reduce the premature wear and tear of fleet vehicles.

4. Improved Safety

Predictive maintenance prepares fleets for possible mechanical failures as they can monitor parts before they fail, which improves driving safety and reduces the risk for any accidents.

5. Improved Fleet Performance

Fleet managers are provided with data analytics on fleet performance with reported usage, and maintenance efficiencies which helps them make firmer decisions for maximizing fleet usage.

Predictive Maintenance Software vs. Traditional Maintenance

| Feature | Traditional Maintenance | Predictive Maintenance Software |

|---|---|---|

| Approach | Scheduled/Reactive | Data-driven/Proactive |

| Downtime | Higher risk | Minimized |

| Cost | Often higher | Reduced through early detection |

| Data Usage | Minimal | Real-time, AI-based |

| Decision-making | Manual | Automated insights and recommendations |

By leveraging predictive maintenance software, fleets gain a competitive edge, ensuring higher efficiency and cost savings compared to traditional methods.

Why Fleetblox Is a Leading Predictive Maintenance Solution

Fleetblox is an example of a cutting-edge, cloud-based predictive maintenance solution that solves some well-known fleet management challenges:

- Device-Free Monitoring – Fleetblox is not reliant on extra hardware installations, therefore minimizing the complexity and cost of implementation.

- AI-Powered Insight – Fleetblox analyzes vehicle data to predict maintenance, giving managers the opportunity to have effective conversations about typically un-foreseeable maintenance.

- Aggregate Maintenance Reports – These reports or dashboards provide visibility to keep managers informed and help them make smart choices.

- Cloud-Based – Because Fleetblox is cloud-based it keeps data secure and enables complete remote collaboration and other tasks across many fleets’.

With all these features, Fleetblox allows fleet operators to reduce downtime, reduce maintenance costs, and improve overall fleet performance in some cases before a vehicle ever leaves the yard.

Predictive Maintenance Tools You Should Know About

Though maintenance software will handle most of the heavy lifting, it’s still beneficial to understand the tools that support it:

- Telematics Sensors: Monitor engine and vehicle performance in real time.

- Diagnostic Algorithms: Learn from the data you collect and start picking up on early signs of part wear.

- Cloud Dashboards: Centralize your fleet management data.

- Automated Alerts: Alarms managers when a vehicle appears to need attention.

These tools integrated with software systems like Fleetblox create a complete system to support fleets staying up and getting better.

Conclusion

Predictive maintenance is changing the way we manage fleets. Making the shift from reactive and scheduled maintenance to predictive, AI-based maintenance, allows fleet managers to lower downtime, lower costs, increase safety and extend the life of vehicles.

Fleet software such as Fleetblox makes predictive maintenance more viable and accessible for fleet managers, providing real-time monitoring, AI analytics, and cloud-based reporting for better fleet management decisions.

For any organization that operates a fleet of vehicles, the adoption of predictive maintenance software, is more than an option, it is a strategic operational necessity to remain competitive and operationally-efficient.

Frequently Asked Questions

Q1: What does predictive maintenance mean?

Predictive maintenance is the technique of using data and AI, to understand if a vehicle is in trouble, or likely to have trouble before there is any downtime.

Q2: How does predictive maintenance software work?

It collects vehicle data, and analyzes it through artificial intelligence (AI) and sends alerts or advise maintenance that is needed before a breakdown.

Q3: What are the advantages of predictive maintenance?

Reducing downtime, reducing the cost of repairs, enhancing the life of the vehicle, improving safety and enhancing efficiency of the fleet overall.

Q4: How does Fleetblox support predictive maintenance?

Fleetblox continually monitors the current health of your fleet in realtime, helps predict your maintenance needs, and provides actionable insights.

Q5: What are the three types of predictive maintenance?

- Condition-Based Maintenance (CBM) – condition-based maintenance relies on real-time vehicle data to determine when maintenance is needed.

- Usage-Based Maintenance (UBM) – where maintenance is carried out after so many miles or hours.

- Time-Series Predictive Analytics – where modeled failures are predicted based on historical data.

Q6: What is the main goal of predictive maintenance?

To avoid failure before it occurs, reduce downtime and repairs and enhance fleet efficiency.