Explore how Fleetblox is changing the fleet maintenance landscape with AI-enabled predictive maintenance, intelligent diagnostics, and real-time monitoring. See how smart maintenance software helps reduce downtime, improve asset life, and maximize fleet efficiency and profitability.

Fleet maintenance is the backbone of a successful transportation or logistics organization. Each mile your fleet travels has an impact on your costs, safety, and efficiency. The traditional methodologies of maintenance can lead to unexpected breakdowns, high service costs, and compliance concerns.

This is where Fleetblox is able to help and provide an intelligent, predictive, and automated fleet maintenance solution, maximizing the smooth operation of your fleet. By merging AI-enabled diagnostics, real time monitoring, and smart scheduling with intelligent decisions all in one app, Fleetblox is able to assist you and ensure that every asset operates at optimal performance while at the same time reducing your fleet operational costs.

Fleet Maintenance in Fleet Management: Why It Matters

Fleet maintenance is defined as the practice of ensuring your vehicles are always working at the best possible condition. Fleet maintenance encompasses regular service or inspection of vehicles, as well as repair after a vehicle has encountered problems. Fleet maintenance is performed with the understanding that it is critical to keeping the fleet reliable, operable, safe, and compliant with industry and regulatory vehicle standards.

All that being said, the way fleets have looked at fleet maintenance in the past was very much reactionary. Fleet services awaited issues and broke down or needed maintenance before repairs were implemented. Reactionary maintenance creates increased fleet downtime, unplanned fleet operating costs, and can contribute to reduced life expectancy for a vehicle.

Modern fleets require a recognizable change away from traditional maintenance administration. Fleets need a preventative maintenance approach; one that anticipates vehicle issues before they occur. Fleet maintenance software and predictive maintenance and all has and will be the way forward for fleets of all sizes.

Fleet Maintenance Software for More Progressive Fleet Management

Fleet maintenance software creates a digital log of every component of fleet management. Rather than have manual records of every service day or logs in spreadsheet, fleets can now track the health of every vehicle. Fleetblox creates a cloud based system where fleet operators and managers will have full sight of the fleet’s maintenance practice. Every maintenance activity will be maintained from scheduling inspections to the assignment of technicians, the approval of repairs and any condition reports.

One of the most significant advantages of fleet maintenance software:

- Fleet maintenance will be managed more easily through automation.

- Log of current vehicle maintenance will be instantly accessible.

- Sustainable logs of worked performed on each vehicle relative to inspections or repairs will be customizable for a fleet operator or manager with different workflows.

- Predictive analytics will included in the system and fleets will use hard facts for navigating decision making.

Moving to a cloud based, or digital approach for vehicle maintenance will make your fleet more efficient, transparent, and save on maintenance costs.

Predictive Maintenance: How AI Improves Vehicle Health & Uptime

The system of predictive maintenance operates through real-time vehicle data analysis which Artificial Intelligence systems and machine learning algorithms perform. The system forecasts equipment breakdowns before they happen so you can handle maintenance tasks before they interfere with normal operations.

Fleetblox operates through its predictive diagnostic technology which sends out smart notifications to detect engine performance issues and brake wear and tire pressure irregularities. Emergency repair costs become more expensive when problems develop because emergency repair costs become more expensive.

Predictive maintenance enables you to :

- Prevent downtime with early detection

- The system requires maintenance and repair less frequently.

- The organization maintains its assets through preventive maintenance which extends their operational life.

- Maintain fleet reliability and safety

The method produces better results than other methods while saving money and enhancing both fleet operational time and efficiency.

Common Fleet Maintenance Challenges and How AI Solves Them

Managing fleet maintenance can be cumbersome without the help of some kind of technology. Let’s look at some of the commonplace problems and see how Fleetblox can mitigate those issues.

1. Reactive Maintenance

- Repairs to fleet vehicles take place only once the vehicle breaks down, and there is no predictive mechanism in place.

- Breakdowns are unplanned and incur more delays in payment and freight delivery.

- Repairs that take place on scene are costly because of the unplanned labor and cost of parts.

- Unplanned downtime shortens productivity and negatively affects profitability.

Solutions: Predictive maintenance via AI learns the early signs of a vehicle breakdown. It intervenes to save money with preventable breakdowns, and increases fleet downtime, or productive hours.

2. Fragmented or Manual Vehicle Maintenance Records

- Documentation of maintenance data is conducted on spreadsheets, paper logs, or emails.

- No complete service history exists which makes it difficult to make a warranty or compliance case.

- Time is wasted searching for documentation and records, and making decisions with limited information and absence of sources.

- Inventory issues lead to unnecessary expenses in operations.

Solutions: Centralized vehicle maintenance logs will keep the documentation and data of service on one single cloud platform that can be accessible, tracked, and audited.

3. Absence of a Standardized Maintenance Manual for Fleets

- Each technician has their own list to follow and there are no uniform standards.

- Repairs vary, creating consistent issues.

- There is a greater risk of compliance/audit inability.

- A damaged brand identity due to poor maintenance quality.

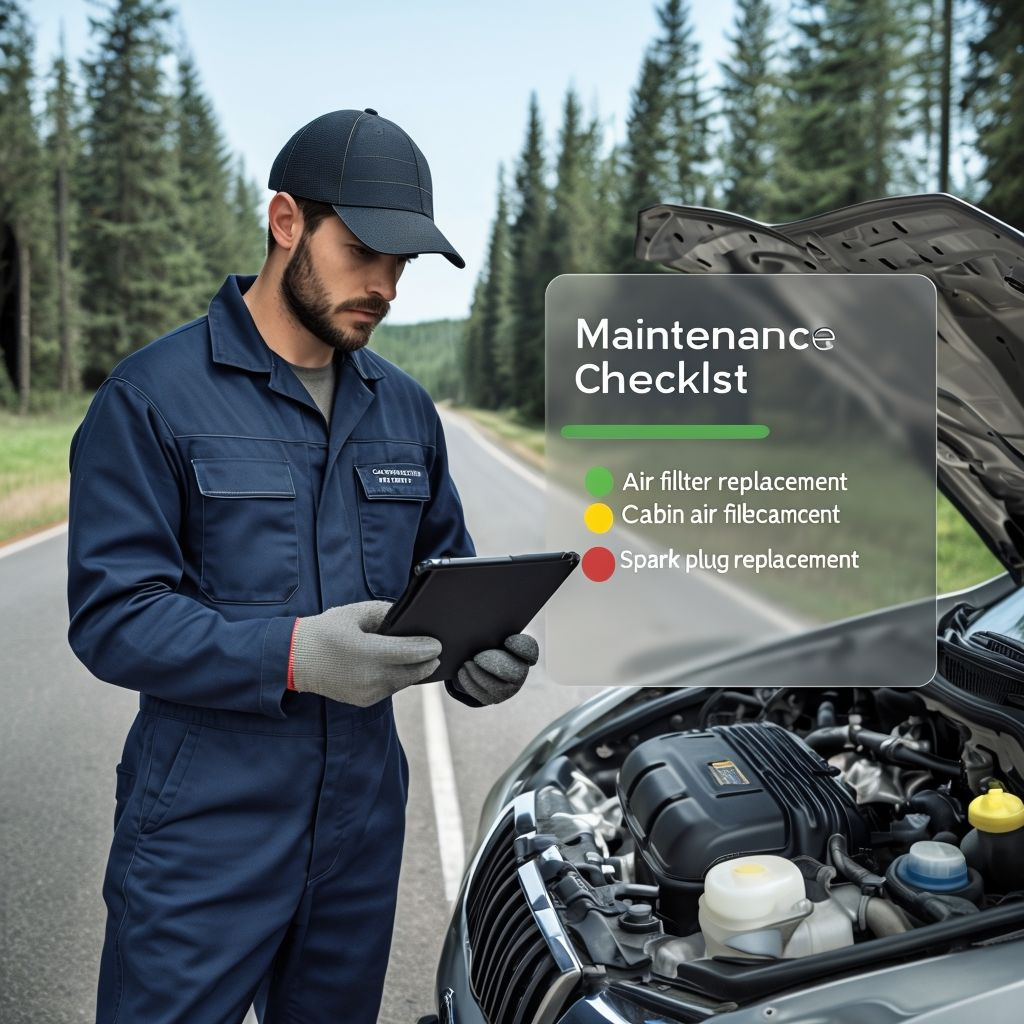

Fleetblox Solution provides a digital maintenance manual which offers technicians a standardized checklist to follow for achieving uniform repair quality.

4. Poor Workflow Management for Maintenance

- The process of manual data entry and task distribution leads to operational confusion and work interruptions.

- Missed or delayed maintenance tasks.

- No accountability in technician performance.

- Increased downtime and inefficiency.

Fleetblox Solution: Improved workflow management-task created-technician assigned- approval workflow-maintain accountability at every step.

5. Lacking Predictive Diagnostics and Routine Inspections

- No remote diagnostics or predictive intelligent fault detections.

- Repeat repairs due to not addressing the real issue.

- Wasted time and resources on unnecessary replacements, components, or parts.

- More downtime and shortened lifespan for vehicles.

Fleetblox Solution: AI-driven predictive diagnostics through remote monitoring for each vehicle that catches problems from the beginning and offers real-time alerts for maintenance needs of the fleet.

6. Compliance and Safety Risk

- If logs are missing or there are inaccuracies, this is a liability and an audit concern.

- Fines or operational shutdowns during safety audits.

- Increase in insurance premiums lacking documentation of required pre-trip inspection.

Fleetblox Solution: The platform makes compliance simple with tracking with automated reports and digital logs for keeping the fleet audit-ready for compliance as needed.

How Fleetblox Addresses These Issues

Onboard & Centralize

Integrate the details of each vehicle; VIN, model and year produced, current mileage and service history; into the Fleetblox system.

Outcome: A centralized, cloud-based vehicle maintenance log that eliminates the multiple records you currently manage.

Digitalize the Joint Fleet Maintenance Manual

Either upload or customize your vehicle maintenance checklists within Fleetblox.

Outcome: Consistent quality control, reduced recurring vehicle maintenance issues, and controlled quality of service.

Activate Predictive Maintenance

Turn on Fleetblox AI-enabled predictive maintenance and monitor the health of your fleet (real-time maintenance log).

Outcome: Reduce breakdowns and unanticipated vehicle repairs via early fault detection, then plan repair work into your calendar.

Automate Maintenance Management

Create and automate internal processes and/or procedures (Task creation–Technician assignment–Approval tracking).

Outcome: Own the responsibility of making sure maintenance happens without micromanaging repairs or downtime.

Use Remote Diagnostics & Intelligent Alerts

Set up remote diagnostics and intelligent alerts to notify you of failures, including how long it will take to repair each failure.

Outcome: Your technician won’t waste time troubleshooting, and you will not have to be involved in the conversation. The repair will be better for your business’s bottom line and drivers.

Auto-Logging & Compliance Reports

Fleetblox logs every service, inspection, and repair and/or replacement of parts automatically.

Outcome: Audit log of all repairs, inspections, and routine maintenance is instantaneous with no manual intervention.

Analyze Costs and KPIs

Fleetblox uses an analytics dashboard to track maintenance costs, downtime, and key performance indicators (KPIs).

Outcome: You will confidently make all decisions, leveraging real-time data and not anecdotes or assumptions – costs will be lower, and returns will be greater.

Real-World Example

The delivery vehicles of the logistics company experienced multiple brake system failures which caused their shipments to arrive late.

With Fleetblox:

- The system detected abnormal brake wear patterns at an early stage through predictive maintenance.

- The system had an automatic process which sent technicians for repairs before equipment breakdowns occurred.

- At one time, the firm judiciously carried out preventive maintenance to avoid equipment failure so as to cut costs and maintain its delivery schedule.

Why Choose Fleetblox for Fleet Maintenance

Fleet Maintenance Software: Provide your fleet operations with full management by this centralized cloud-based platform.

Joint Fleet Maintenance Manual: Standardized digital processes reduce human error while increasing compliance rates.

Vehicle Maintenance Log: Maintenance activities and repair work, and the results of inspections, are automatically recorded by the system for quick retrieval.

Predictive Maintenance: Artificial intelligence systems detect vehicle problems before they occur which reduces downtime and increases vehicle service duration.

Maintenance Management Workflow: The system lets users monitor all maintenance activities while ensuring complete responsibility for every task from beginning to end.

Analytics & Reports: The system provides maintenance cost data and vehicle uptime statistics and performance metrics which help users make better decisions.

Benefits of AI-Based Fleet Maintenance

- The system sends preemptive warnings through predictive analytics which help you avoid equipment failures.

- The system operates through automated diagnostic methods which combine with intelligent scheduling systems to reduce operational costs.

- The prevention of equipment damage through timely maintenance allows assets to continue operating for longer periods.

- The system maintains audit readiness through digital logs which help organizations maintain their compliance and safety standards.

- A fleet operating at peak efficiency depends on vehicles that receive proper maintenance because they deliver better performance and experience reduced repair needs.

- The company achieves better return on investment through lower maintenance expenses and longer equipment operational periods which generate increased revenue.

Start Your Fleet Remote Diagnosing Today

Fleet maintenance is no longer a matter of guesswork. With Fleetblox’s AI-powered fleet maintenance platform, you will always know the exact health of your fleet so that good decisions can be made to reduce downtime and increase profitability.

Conclusion

Gone are the days when fleet maintenance was just about fixing a vehicle. It is now a matter of preventive maintenance-a kind where Fleetblox provides predictive maintenance, intelligent diagnostics, and AI-and workflow-driven maintenance strategies, thereby granting increased uptime, optimized costs, and longer vehicle life.

If your fleet size falls anywhere between 10 and 10,000, Fleetblox is your go-to for ensuring your fleet runs smoothly and profitably every single day.

FAQS

1. What is fleet maintenance?

Fleet maintenance involves routine inspections, servicing, and repairs to keep a fleet of vehicles in maximum working condition, ensuring reliability, safety, and compliance.

2. What is the role of a fleet maintenance manager?

A fleet maintenance manager oversees the maintenance of vehicles, schedules repairs, manages technicians, ensures compliance to regulations, controls costs, and ensures that the fleet continues to run smoothly.

3. What is predictive maintenance in fleet management?

Predictive maintenance utilizes AI and real-time vehicle data to find early signs of wear or damage to prevent downtime and reduce the costs of maintenance.

4. How does fleet maintenance software enhance efficiency?

Fleet maintenance software streamlines the scheduling of repairs, tracks repairs made on a vehicle, and maintains digital records providing the manager with a simple task to manage repairs, meeting deadlines.

5. What are the components of a vehicle maintenance log?

Records of services completed (dates and services completed), inspection results, names of technicians who worked on the vehicle, parts that were replaced, and costs of repairs all kept digitally for easy access.

6. How is Fleetblox effective in modern fleet maintenance?

Fleetblox is an AI-driven diagnostics and remote monitoring, predictive maintenance, and cloud-based collaborative solution for smart fleet management.